Micro-Fulfillment Centers: Cut Last-Mile Costs by 15% in 2025

Micro-fulfillment centers are revolutionizing e-commerce logistics by strategically placing inventory closer to customers, thereby significantly reducing last-mile delivery expenses and achieving an estimated 15% cost cut by 2025.

The landscape of retail is undergoing a profound transformation, driven by consumer demand for faster, cheaper, and more convenient delivery. In this evolving environment, micro-fulfillment centers: cutting last-mile delivery costs by 15% in 2025 emerges as a pivotal strategy, offering a pragmatic solution to one of e-commerce’s most persistent challenges: the expensive and complex last mile.

Understanding micro-fulfillment centers

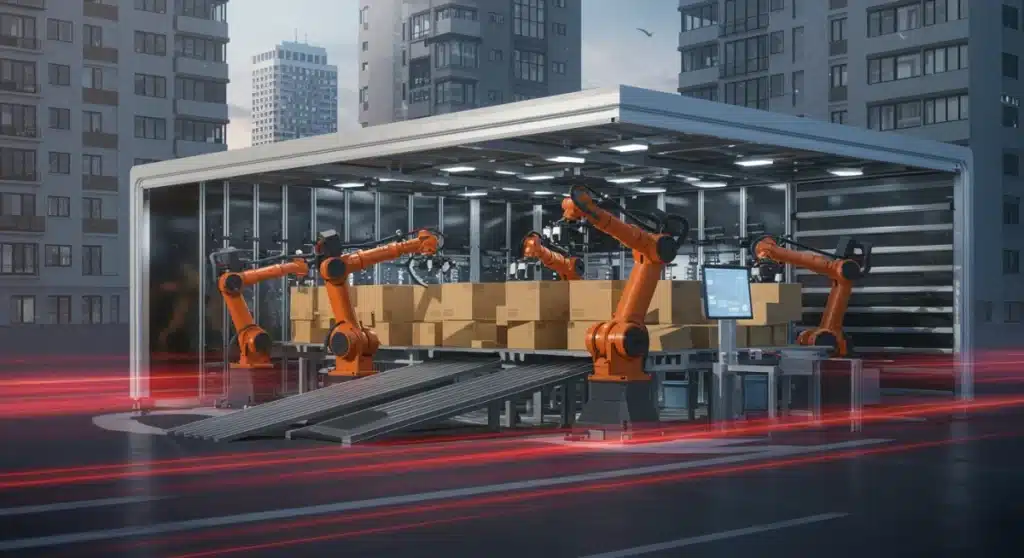

Micro-fulfillment centers (MFCs) represent a paradigm shift in urban logistics, blending the storage capabilities of traditional warehouses with the speed and proximity of local retail. These facilities are typically smaller than conventional distribution centers, strategically located in urban or suburban areas, often within existing retail spaces or dedicated compact footprints.

Their primary function is to bring inventory closer to the end consumer, dramatically shortening delivery distances and times. This strategic placement is crucial for retailers aiming to meet the escalating expectations for rapid delivery, often within hours rather than days.

The strategic advantage of proximity

By placing goods within a few miles of customers, MFCs bypass the need for long-haul transportation for individual orders, which is a major cost driver in traditional supply chains. This localized approach not only accelerates delivery but also reduces the carbon footprint associated with logistics.

- Reduced transportation costs: Shorter distances mean less fuel consumption and fewer vehicle miles.

- Faster delivery times: Enables same-day or even hourly delivery options.

- Improved customer satisfaction: Meets demand for instant gratification in e-commerce.

- Optimized inventory management: Stock is closer to demand, reducing stockouts and overstocking.

The integration of automation, such as robotics and AI-driven inventory systems, further enhances the efficiency of MFCs. These technologies allow for high-density storage and rapid order picking, processing a large volume of orders in a compact space with minimal human intervention. This combination of strategic location and advanced automation is what makes MFCs a powerful tool for modern retail.

The last-mile delivery challenge

Last-mile delivery, the final leg of an item’s journey from a distribution center to the customer’s doorstep, is notoriously inefficient and expensive. It accounts for a disproportionately large share of total shipping costs, often consuming 50% or more of the total logistics budget for e-commerce companies. This segment is fraught with complexities, from navigating dense urban traffic to managing multiple delivery stops and unpredictable customer availability.

Traditional logistics models, designed for bulk shipments and large distribution centers, are ill-suited for the granular demands of last-mile delivery. The increasing volume of online orders, coupled with consumer expectations for free and fast shipping, has amplified these challenges, pushing retailers to seek innovative solutions.

Key pain points in last-mile logistics

Several factors contribute to the high cost and inefficiency of last-mile delivery. These include the sheer number of individual stops, the variability of delivery locations, and the need for specialized vehicles or methods for urban environments.

- Traffic congestion: Urban areas are prone to delays, increasing delivery times and fuel costs.

- Customer density: While urban areas have high customer density, the scattered nature of individual deliveries still poses challenges.

- Labor costs: Drivers’ wages and benefits represent a significant portion of operational expenses.

- Failed deliveries: Redelivery attempts or returns due to customers not being home add substantial costs.

The pressure to offer competitive shipping options while maintaining profitability has led many businesses to a breaking point. Without a fundamental shift in strategy, the costs associated with last-mile delivery are projected to continue rising, making it unsustainable for many e-commerce operations. This makes the ability of micro-fulfillment centers to tackle these issues directly a game-changer.

How micro-fulfillment centers cut costs

The core mechanism by which micro-fulfillment centers reduce last-mile delivery costs lies in their ability to minimize travel distance and optimize order processing. By strategically situating inventory closer to consumers, MFCs drastically shorten the final leg of delivery, which is the most expensive part of the supply chain.

Instead of dispatching orders from a distant, centralized warehouse, MFCs enable local fulfillment, transforming a long, costly journey into a short, efficient sprint. This proximity allows for more frequent and flexible delivery options, often leveraging existing local delivery networks or even in-store pickup models.

Operational efficiencies through automation

Beyond geographical advantage, MFCs leverage advanced automation to achieve significant operational efficiencies. Robotics, automated storage and retrieval systems (AS/RS), and sophisticated software orchestrate the entire fulfillment process, from receiving goods to picking, packing, and dispatch.

This automation reduces the reliance on manual labor, which is a major variable cost, and minimizes errors, leading to fewer returns and improved customer satisfaction. The speed and accuracy of automated systems mean orders can be processed faster, increasing throughput and capacity within a smaller physical footprint.

- Automated picking and packing: Robots handle repetitive tasks, increasing speed and accuracy.

- Reduced labor costs: Less need for extensive human staff, particularly for routine tasks.

- Optimized space utilization: High-density storage systems maximize efficiency in compact urban locations.

- Lower fuel consumption: Shorter delivery routes directly translate to less fuel expense.

The combined effect of reduced transportation distances and enhanced operational efficiency through automation makes MFCs a powerful tool for achieving substantial cost savings in last-mile delivery, contributing significantly to the projected 15% reduction by 2025. This integrated approach addresses both the logistical and operational challenges inherent in modern e-commerce fulfillment.

Projected cost savings by 2025

Industry analysts and logistics experts project that the widespread adoption of micro-fulfillment centers will lead to a significant reduction in last-mile delivery costs, with estimates reaching up to 15% by 2025. This optimistic outlook is based on the proven efficiencies MFCs bring to the supply chain, directly addressing the most expensive segment of the delivery process.

The savings are not merely hypothetical; they are a direct outcome of shorter delivery routes, reduced fuel consumption, optimized labor utilization through automation, and fewer failed deliveries. As more retailers integrate MFCs into their logistics networks, the cumulative effect of these efficiencies will reshape the economic model of e-commerce delivery.

Factors driving the 15% reduction

Several converging trends and technological advancements contribute to the feasibility of this 15% cost reduction. The maturation of automation technologies, the increasing availability of suitable urban real estate, and a growing understanding of network optimization are all playing a role.

- Technological advancements: Improved robotics and AI for inventory management become more affordable and efficient.

- Scalability of solutions: MFC models are becoming more flexible, allowing businesses of various sizes to implement them.

- Consumer demand: Pressure for faster, cheaper delivery forces innovation in logistics.

- Real estate innovation: Creative use of urban spaces, including dark stores and existing retail footprints, for MFCs.

Furthermore, the data collected from MFC operations allows for continuous optimization of routes, inventory placement, and labor scheduling, leading to incremental but significant cost improvements over time. The initial investment in MFC infrastructure is offset by these long-term operational savings, making them an attractive proposition for businesses looking to enhance their competitive edge. The projected 15% reduction is a conservative estimate, with some models suggesting even greater savings as technology advances and adoption scales.

Implementation challenges and considerations

While the benefits of micro-fulfillment centers are clear, their implementation is not without challenges. Successfully deploying MFCs requires careful planning, significant upfront investment, and a thorough understanding of local market dynamics. Retailers must navigate complex real estate decisions, integrate sophisticated automation, and manage the transition from traditional fulfillment models.

One of the primary hurdles is the capital expenditure required for automated systems and facility setup. This can be substantial, making it a barrier for smaller businesses or those with limited access to funding. However, third-party logistics (3PL) providers are increasingly offering MFC-as-a-service, lowering the entry barrier.

Navigating the complexities of MFC deployment

Beyond capital, the operational complexities of running an MFC demand a high level of expertise. This includes managing advanced robotics, integrating various software systems, and ensuring seamless coordination with last-mile delivery partners. The urban environment itself presents challenges, such as zoning restrictions, limited space, and traffic congestion for inbound and outbound logistics.

- High initial investment: Automation and facility setup costs can be prohibitive.

- Integration complexities: Connecting MFC systems with existing e-commerce platforms and delivery networks.

- Real estate constraints: Finding suitable and affordable urban locations.

- Workforce adaptation: Training staff to operate and maintain automated systems.

Moreover, effective inventory management across a distributed network of MFCs requires sophisticated forecasting and allocation strategies to ensure products are available where and when consumers need them, without incurring excessive carrying costs. Despite these challenges, the long-term strategic advantages and cost savings offered by MFCs are compelling enough for many retailers to invest in overcoming these obstacles, recognizing them as essential for future growth and competitiveness.

The future of retail logistics

The emergence and rapid adoption of micro-fulfillment centers signal a fundamental shift in the future of retail logistics. As consumer expectations for speed and convenience continue to rise, and as urban populations grow, the traditional centralized warehousing model is becoming increasingly unsustainable for last-mile delivery. MFCs offer a scalable and adaptable solution that aligns with these evolving market dynamics.

Looking ahead, we can expect to see further innovation in MFC design, including more compact footprints, enhanced automation, and greater integration with smart city infrastructure. The concept of a ‘dark store’ – a retail location converted entirely into an MFC – is likely to become more prevalent, blurring the lines between retail space and fulfillment center.

Evolving technologies and partnerships

The future will also bring advancements in the technologies that power MFCs. AI and machine learning will play an even greater role in demand forecasting, inventory optimization, and route planning, making MFC operations even more efficient and predictive. Robotics will become more sophisticated, capable of handling a wider range of products and tasks with greater agility.

- Increased automation: Further development in robotics and AI for greater efficiency.

- Hyperlocal delivery networks: Stronger partnerships with local delivery services and gig economy platforms.

- Sustainable practices: Emphasis on electric vehicles and eco-friendly packaging for last-mile.

- Data-driven optimization: Leveraging big data for predictive analytics in inventory and demand.

Furthermore, partnerships between retailers, technology providers, and logistics companies will become crucial for building robust and resilient MFC networks. These collaborative ecosystems will drive innovation, share best practices, and collectively address the challenges of urban logistics. The trajectory points towards a highly distributed, automated, and responsive supply chain, with micro-fulfillment centers at its heart, ensuring that retailers can meet future demands while maintaining profitability.

| Key Aspect | Brief Description |

|---|---|

| Proximity Advantage | MFCs locate inventory near customers, drastically cutting last-mile travel distances and costs. |

| Automation Efficiency | Robotics and AI optimize order picking and packing, reducing labor needs and errors. |

| Cost Reduction Target | Projected 15% cut in last-mile delivery costs by 2025 due to MFC adoption. |

| Challenges | High initial investment and integration complexities are key hurdles for adoption. |

Frequently asked questions about micro-fulfillment

An MFC is a compact, automated warehouse typically located in urban areas, often within or near existing retail stores. It stores and processes e-commerce orders closer to customers, enabling faster and more cost-effective last-mile delivery compared to traditional, large-scale distribution centers.

MFCs reduce costs by shortening delivery distances, leading to lower fuel consumption and less vehicle wear. Automation within MFCs also decreases labor costs and increases order processing efficiency, minimizing errors and improving overall delivery economics for retailers.

Automation, including robotics and AI, is central to MFC operations. It enables high-density storage, rapid and accurate order picking, and efficient packing. This technology boosts throughput, reduces operational costs, and allows MFCs to handle large order volumes in a small footprint.

Key challenges include the significant upfront capital investment for automation and facility setup, finding suitable urban real estate, and the complexities of integrating new systems with existing supply chains. Workforce training and managing distributed inventory are also critical considerations.

By 2025, MFCs are expected to significantly enhance e-commerce efficiency, enabling faster delivery times and substantially reducing last-mile costs by approximately 15%. This will improve customer satisfaction, increase retail profitability, and reshape urban logistics infrastructure for online shopping.

Conclusion

The strategic adoption of micro-fulfillment centers is poised to fundamentally redefine the economics of e-commerce delivery by 2025. By addressing the inherent inefficiencies and high costs of last-mile logistics through proximity and advanced automation, MFCs offer a compelling pathway for retailers to achieve significant cost reductions, estimated at 15%. This shift is not just about saving money; it’s about building a more responsive, sustainable, and customer-centric supply chain that can meet the evolving demands of the modern consumer. As technology advances and implementation challenges are overcome, micro-fulfillment centers will undoubtedly stand as a cornerstone of competitive retail in the years to come.